I’ve been riding bikes of all kinds since the 1980s and done some big rides. But the Fezzari Timp Peak I bought in late 2014 was the first really good mountain bike I owned. I got this bike to ride Kokopelli’s Trail with Bikerpelli in 2015. Great ride! This bike has also proven itself on some of the biggest, hardest rides in the country, like the Oregon Trail Gravel Grinder, 350+ miles and 30,000′ of climbing.

Carbon frame, carbon wheels, SRAM XX1, dual suspension, dropper seat, weighing 25-26 lbs. ready to ride. It’s been a great bike but no bike is perfect and they all require maintenance. Here are some of of the problems I’ve encountered and how I solved them.

Some of these issues are basic recurring maintenance. Others are caused by using aluminum or weak alloys in critical parts instead of appropriate materials like steel or brass.

SRAM Sticky Brakes

The first problem was the dreaded SRAM sticky brakes. The brake lever pistons gradually grow (yes they physically get larger!) and get stuck in the cylinder. In my case it took a few years to happen. Here is my fix. That worked for a year or so, then they got sticky again. At that point instead of sanding down the pistons again, I replaced them with aftermarket metal pistons. These have perfect fit & function, came with the o-rings, and fix the problem permanently.

Since then I’ve overhauled the levers with the complete rebuilt kit. This includes all-new seals and pistons, among other things. It made a big improvement so I’ll be repeating this every 3-5 years.

Frame Suspension Pivot Bushing

After a few years, the frame developed a bit of play. Most of the frame suspension pivots use bearings, which I serviced (cleaned, re-greased). But one of them uses a bushing, and that’s where the play developed. Over time the bushing wears and needs replacing. I contacted Fezzari and they told me:

The bushings at the main rocker pivot are IGUS L289 sleeve bushings. The part number for them is LFM-1012-06. The “-06” part of this part number is in reference to the bushing length which is 6mm.

However, what I would recommend trying is a bushing with a 10mm or 12mm bushing length (part no. LFM-1012-10 & LFM-1012-12, https://www.igus.com/product/?artnr=LFM-1012-10). It will allow for a bit more overlap with the frame and should help reduce the play.

I ordered that part, 12mm size. It fit perfectly and the frame is like new again. Actually, better than new!

Another issue that gradually develops is side-to-side play. The frame pivot that meets the bushing has a shiny black surface (paint?) that gradually wears down, allowing this play. The solution is to place thin spacer washers around the bushing’s core, “inside” between the bushing face and the frame. This pushes the bushing faces slightly outward to eliminate the play. The best washer size is 1/2″ inside diameter, 3/4″ outside diameter, and 1/32″ thick.

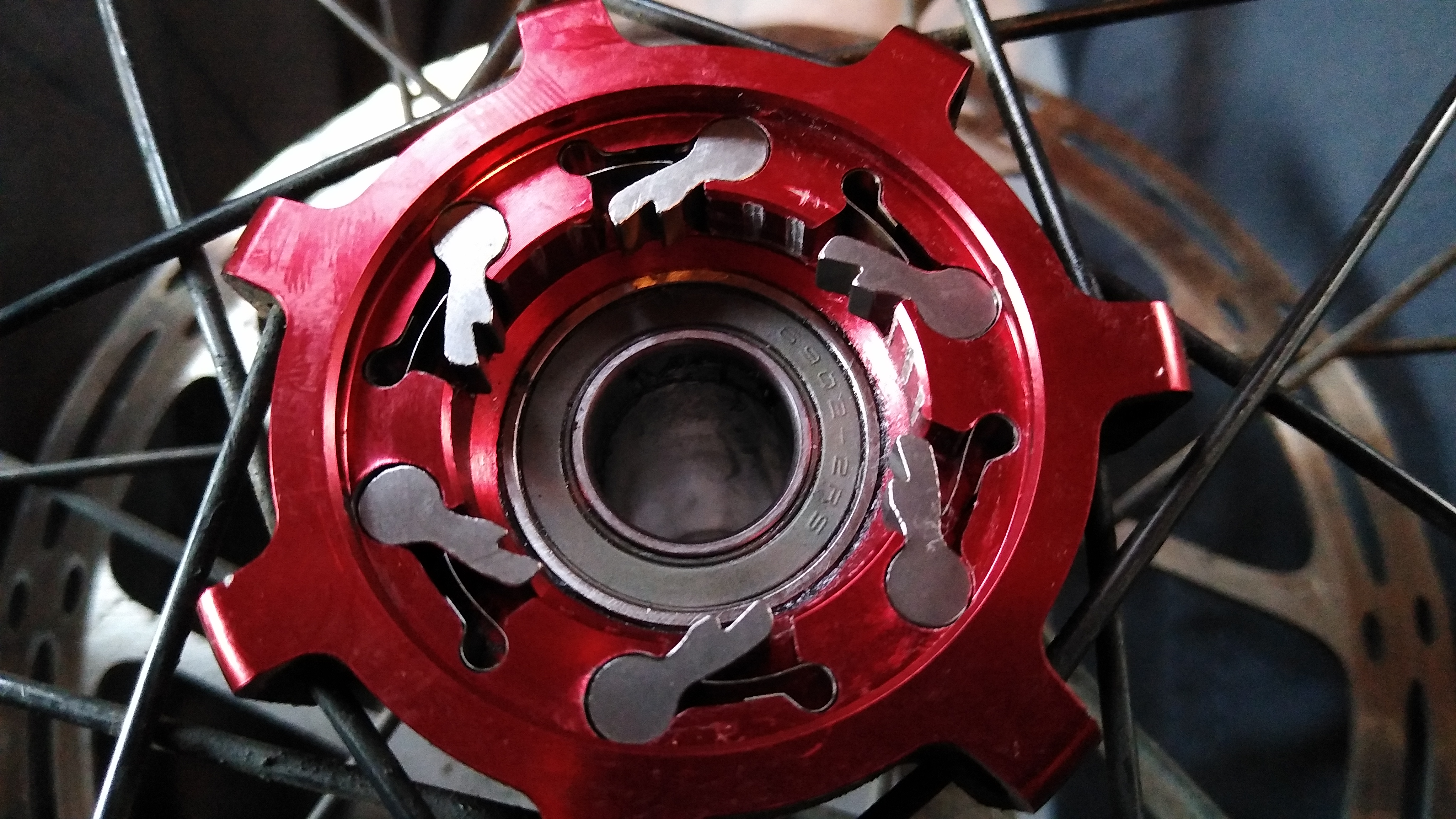

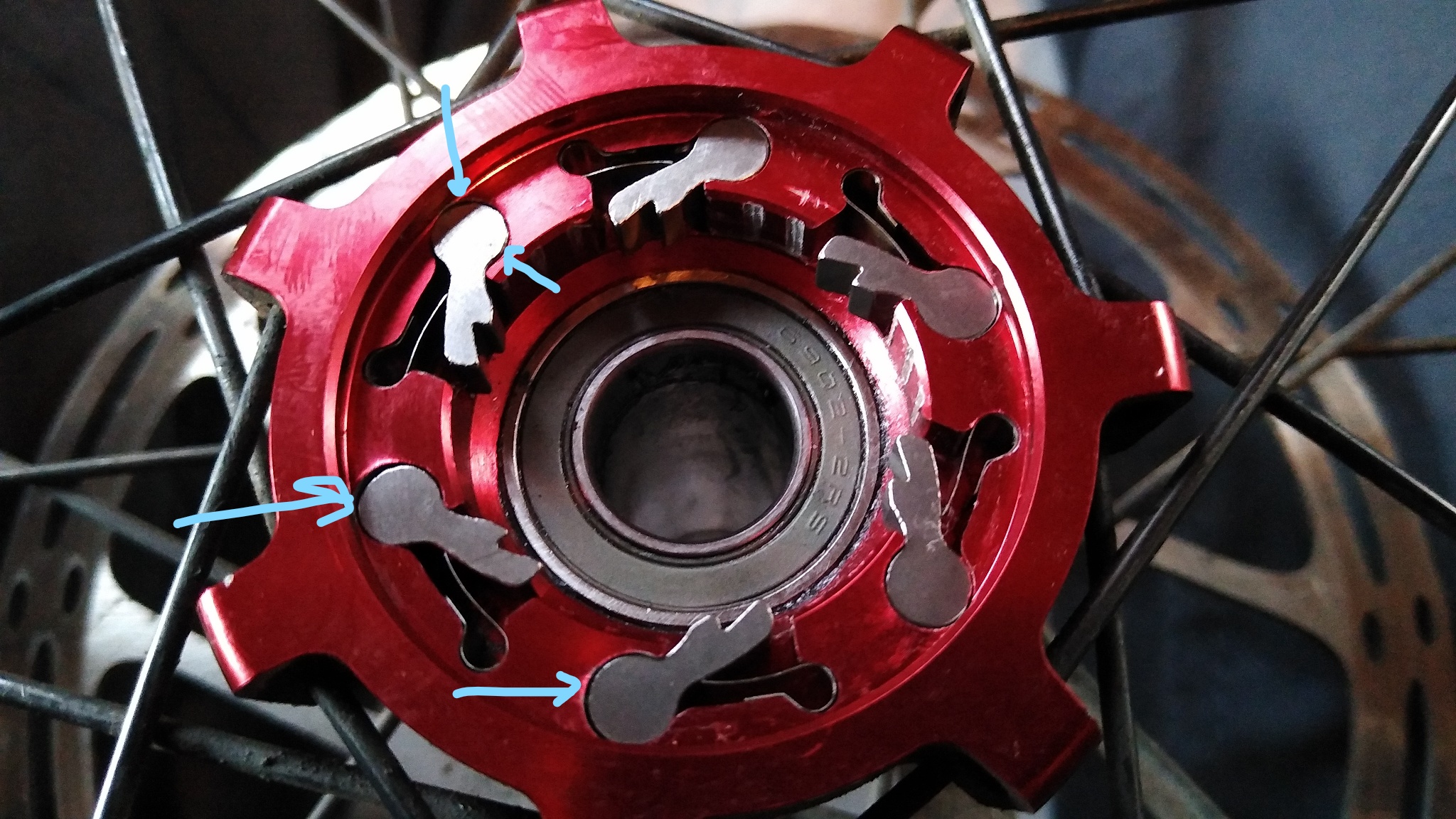

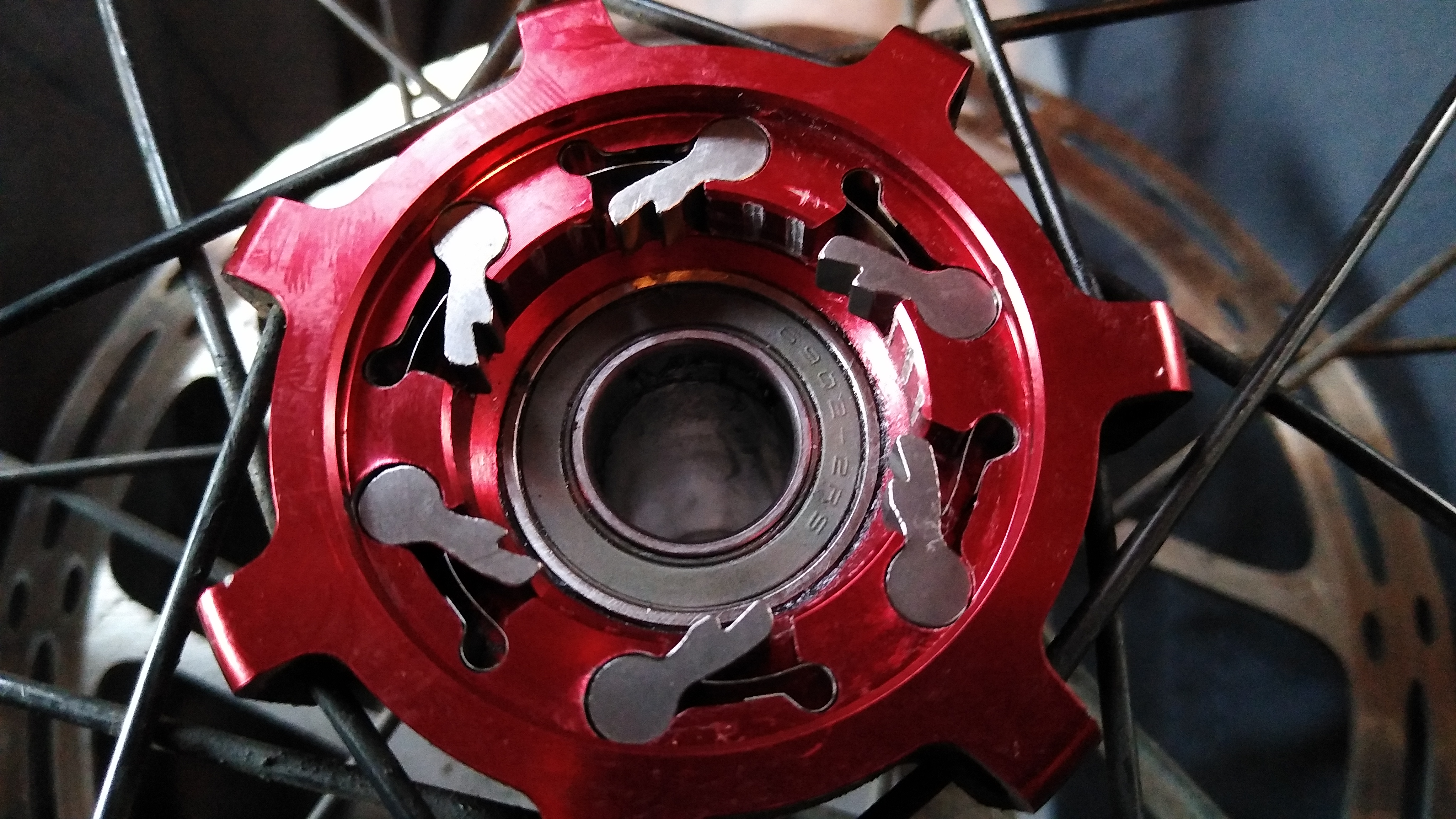

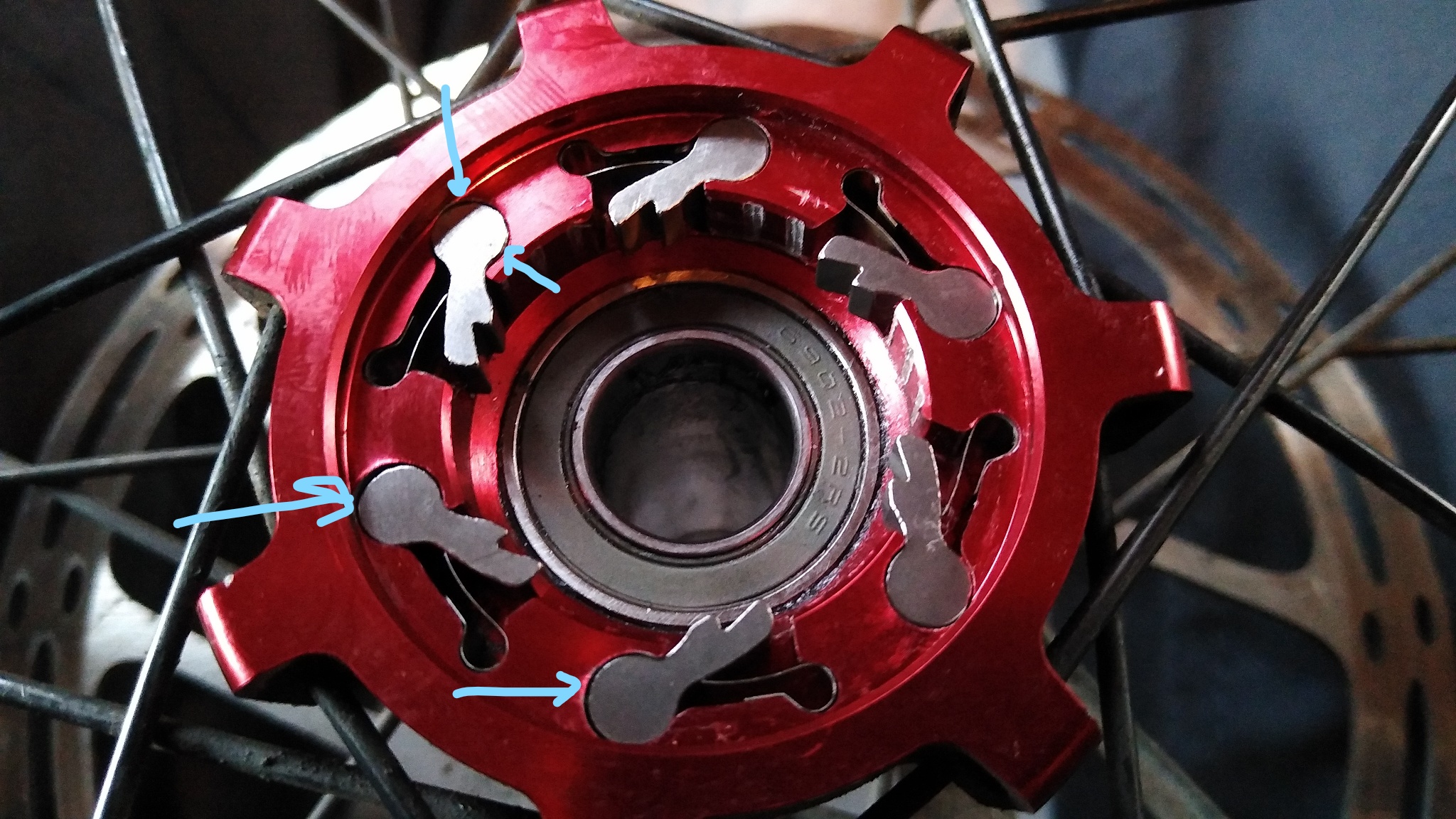

Rear Hub Failure

The last problem I encountered was a severe ride-stopper. It stranded me out in the desert near Moab and I had to walk my bike out. Going up a hill, the bike suddenly made a horrible clacking sound and the pedals were free-spinning. The chain was completely intact. I took apart the rear hub by the side of the road to discover that pawls that engage the freehub ratchet had worn down and were slipping. No way to fix that by the side of the road. And after I hiked back to the car and drove to town, none of the bike shops in Moab could fix it either.

No way to fix that by the side of the road. And after I hiked back to the car and drove to town, none of the bike shops in Moab could fix it either.

Fezzari connected me to Hayes/Reynolds where I contacted a guy named Dan and ordered the parts:

Part 21290 "Reynolds XD Driver Body" replaces the cassette ratchet gear.

Part 20702 "2015-2016 Attack Assault Strike Hub Rebuild Kit" replaces the hub pawls (and other things).

When I told Reynolds this unusual and catastrophic failure happened to a bike that was only a few years old, equipped with some of their best carbon wheels, and left me stranded having to hike out of the desert pushing my bike, they gave me a 25% discount. The above parts fixed it.  The pawls were the essential part; they were visibly and obviously worn down and rounded off. The freehub ratchet wasn’t obviously worn, but I replaced it anyway since it could have had non-visible damage from the damaged pawls slipping over it.

The pawls were the essential part; they were visibly and obviously worn down and rounded off. The freehub ratchet wasn’t obviously worn, but I replaced it anyway since it could have had non-visible damage from the damaged pawls slipping over it.

After just over a year, I inspected the new pawls to find that they had visible wear, though they were still working. I ordered another set of pawls, installed them, and kept these as emergency replacements.

It’s frustrating to note that if these pawls were made of steel, they’d last forever and the wheel would only be a few grams heavier. But they’re made of some kind of lightweight alloy.

Bottom Bracket Crank Arm Spindle Bolt

After servicing the bottom bracket (cleaning & re-greasing bearings) I was re-assembling it. These SRAM cranks have a single bolt on the left (non-drive) side that holds everything together. The spec says tighten to about 52 Nm, or 38 ft.lbs. As I was tightening it, well before it got that tight, I felt it give. I removed it and discovered 2 things:

- The head had sheared off the bolt

- The bolt was made of aluminum (or alloy) — not steel ?!

This is a high torque, high stress bolt. It should be made from steel! Making it from a softer, weaker aluminum alloy is a total fail in design. I’ll gladly pay a weight penalty of a measly 12 grams for the confidence of knowing my cranks won’t fall off the bike. Apparently I’m not the only person who thinks so. Shout-out to one of my LBS, Gregg’s Cycles, who had a replacement bolt in stock. I bet I know why they keep these bolts in stock… <groan>

Details:

- Truativ GXP M15 Crank Bolt

- CR2193

- 11.6900.002.140

- M15/M26

Sadly, it is alloy like the broken one. So it is probably “single-use”. I’m still looking for a steel one, but this one will serve until I find it.

Alloy Spoke Nipples

Descending Olallie, I heard a “ping” from the front wheel so I stopped. A spoke was loose; the nipple head had sheared off. I smoothly bent the free spoke to weave it through adjacent ones so it couldn’t flop around. Fortunately, the wheel is strong enough and with disc brakes I was able to finish the ride slowly.

The Timp Peak came with Reynolds AM 27.5 carbon wheels. Apparently, carbon fiber causes a redox galvanic corrosion reaction with alloy nipples. It starts slowly and progresses incrementally over time, so the wheels may go 5 years or so before it weakens the spoke nipples enough for the heads to shear off. I replaced that spoke with a brass nipple and re-sealed the wheel.

After the OTGG, another spoke nipple head popped off while I was truing the wheel–actually loosening the spoke, not tightening it! At this point I unsealed the wheel and replaced all of them with brass. While doing so, I found 4 others that were already cracked just waiting to break.

<rant>

No carbon wheel should use alloy spoke nipples. Brass will last forever and a set of 28 only weighs about 20 grams more. Alloy may be appropriate for super light road bike wheels, but the weight savings is immaterial on a MTB, considering we typically run 800 gram tires. This is an example of the race to the lightest wheelset at any cost. Reynolds confirmed that their wheel builders use only brass spoke nipples when servicing wheels, even though their OEM wheels come with alloy nipples.

</rant>

Rear Rim

The rear wheel rim delaminated near the outer edge; structure failure. Fortunately, I noticed it after a ride so it didn’t fail while riding. Reynolds replaced it under their lifetime warranty. Normally, this means mailing them your broken wheel, they rebuild a new rim onto your old hub and charge you $150 for the parts (spokes, sealing tape). It takes 6 weeks.

Reynolds replaced it under their lifetime warranty. Normally, this means mailing them your broken wheel, they rebuild a new rim onto your old hub and charge you $150 for the parts (spokes, sealing tape). It takes 6 weeks.

But 6 weeks wouldn’t work. This happened 1 week before the OTGG, a 5-day stage ride I had been training for 18 months. I asked Reynolds support to simply mail me a new rim, I would rebuild the wheel myself. And they did! They don’t make the AM wheels anymore, so now I have the closest match, a Blacklabel 287 (which has off-center spoke holes to equalize spoke dish angles). It arrived 1 day before the big ride, I built the wheel that afternoon (using DT 14 gauge straight-pull spokes and brass nipples) and it all worked out. Now that is just-in-time warranty service!

The new rim has a deeper profile, so the ERD is 9mm smaller, which meant I needed shorter spokes. Split the ERD difference in half means 4mm shorter on each side. But the original spokes didn’t fully protrude from the nipple heads, so I added 1mm (3mm shorter). This way the spokes would pass all the way through the nipple heads which makes it a bit stronger. OTGG was this new wheel’s first break-in ride. It performed flawlessly.

OTGG was this new wheel’s first break-in ride. It performed flawlessly.

Rear Axle

In Sep 2022 riding the John Wayne / Palouse trail, the rear axle broke between Beverly and Othello. This is normally a critical failure that makes the bike un-rideable. At the same time, the derailleur swung forward and sheared off the end stop of the hangar. I was able to MacGyver both the axle and the derailleur in order to ride back to the nearest town and hitch a ride.

Rear Wheel Bearings

While I was replacing the axle I decided also to replace the bearings. They were still in serviceable shape, but not perfectly smooth anymore. I ordered a set of NSK bearings (size 6902) since they’re supposed to be excellent. I cleaned out the rat piss that they use for OEM grease and packed it with Schaeffer’s 221 #2. The bearing was smooth as butter. After installing it (smoothly with a proper bearing press, not whacking it in), it was rough & notchy. I pressed it out and it was smooth again. Weird. So I bought a generic 6902 at the LBS. Same procedure: cleaned out the OEM grease, packed with Schaeffer’s 221 #2, installed. It was smooth as butter installed.

Perhaps the hub’s bearing socket wasn’t perfectly round? Maybe, but 2 other bearings were butter smooth as installed, so seems unlikely.

Perhaps somehow the compression/squeeze forces of the press-fit install, eliminated the bearing’s internal tolerances? Maybe.

Perhaps it was due to the generic bearing being cageless, combined with an imperfectly round bearing socket? The NSK is a caged bearing, which is normally better. Yet perhaps cageless bearings are more tolerant of imperfectly round sockets?

Rear Through-Axle

After riding the bike 15 miles with a broken axle, the through-axle showed metal fatigue right at the point where the axle had snapped. Apparently, this put more stress on the through-axle. It was still serviceable, but due to the visible metal fatigue I replaced it anyway. It’s 12mm OD, 142mm rear dropout spacing, 174mm total length, 20mm of threads at the end, with a 1.75 pitch.

Rear Hub Shell

When the 2nd set of replacement pawls showed signs of wear in only 5 months, I sent Reynolds a photo and asked for a warranty replacement. They studied the photo and found that the pawl pockets machined into the hub are worn & distorted. I took a close look and they’re right! The distortion is only slight and the hub is still serviceable, but its days are numbered.

Looks to me, and to a friend with experienced eyes, Reynolds should have used a harder grade of aluminum alloy. Not only for the hub shell, but also for the pawls, and for the axle (all of which have failed on me).

They offered to warranty the hub shell, which means mailing them the wheel, the rebuild it onto a new hub shell and send it back, charge me $200 for parts (spokes, axle, bearings, freehub) and labor. I asked if they had a parts list because I prefer to do my own work and build my own wheels. They said no, it’s only a service. Which is different from last year, when they mailed me a warranty replacement rim for me to build myself.

That doesn’t sound like a great deal because I can buy top quality parts for less and build the wheel myself. But I do appreciate their sharp eyes in detecting a problem that I overlooked. I suspect they knew what to look for, as this isn’t the first of their hubs that has had this problem. Indeed, after all the problems this rear wheel has given me, I’m not inclined to use another Reynolds wheel. In summary:

- OEM spoke nipples cracked and failed, due to aluminum/carbon redox reaction. I rebuilt the wheels with brass spoke nipples

- Freehub pawls sheared, stranding me in the Moab desert.

- Carbon Rim delaminated; Reynolds sent me a new rim under warranty and I rebuilt the wheel (again).

- Axle broke, stranding me on along the John Wayne Trail.

- Hub shell pawl pockets wore out of shape.